Arduino 4l60e Controller Open Source

- Arduino 4l60e Controller Open Source Download

- Gm 4l60e Controller

- Arduino 4l60e Controller Open Source Free

- Arduino 4l60e Controller Open Source Software

I previously built an MPPT charger ( ). It is very strong and durable, but it always works silently. Arduino is a kind of universal programmable controller, although it is only the “core” and in any case it has been built for general applications; with a little of external hardware (essentially interfaces capable of transferring signals from sensors and to actuators, reducing the EMI which may damage the microcontroller) and an appropriate.

Click on our menu buttons immediately below to find MegaSquirt® information quickly:

|

MegaShift™ Transmission Controller

The MegaShift™ automatic transmission controller code is full-featured code (see features below) designed for the GPIO board from Bowling and Grippo. MegaShift™ (aka. 'MShift™') is designed as a 'universal' flexible DIY automatic transmission controller, adaptable to many electronically controlled transmissions.

MegaShift™ with the GPIO board has been in use since early 2006 in testing in a variety of vehicles, and has been in production since the Fall of 2009. The GPIO board was designed with transmission control in mind - it is not a 'hacked' engine controller with inherent compromises and limitations. It also costs significantly less than a MicroSquirt® controller or a complete MS-II® controller.

You can buy the GPIO board right now from DIYAutoTune (the MShift™ code is free to download).

Applications include the 4L60E and 4L80E 4-speed overdrive transmissions from General Motors (the defaults are for the 4L60E), Chrysler 41te, as well as many other similar electronically controlled automatic transmissions.

Here is a brief, grainy flash video of MShift™ and TunerStudioMS in action on the test bench: MShift_demo.flv (2.5MBytes)

MegaShift™ on the GPIO board has the following features:

- Up to 8 forward speeds,

- Full CAN pas-through configuration and monitoring/datalogging with TunerStudioMS,

- Fully user configurable automatic or manual mode, with user tables for shift speeds and line pressures a based on speed and load,

- switchable 16x9 load by speed by target gear tables (with user settable bins values) for automatic shifting,

- Context sensitive help for all user parameters by pressing F1 button while in any menu in TunerStudioMS (while connected to the Internet),

- User settable over and under-rev limiting (can be disabled if desired),

- Speed in 0.1 mph (or kph) increments,

- Odometer in 0.001 mile (kilometer) increments,

- Full datalogging of speed, gear, odometer, line pressure, instantaneous fuel efficiency, converter slip, etc., etc.

- Provisions for 'paddle' up and down shifter buttons on steering wheel with 'Shift Button Duration' for user settable sensitivity (debounce). The buttons can be separate grounding switches, or a variable voltage signal (that may be adaptable to your horn set-up).

- User settable idle valve and ignition advance 'idle-up' adjustments when stopped in gear to prevent stalling,

- User settable ignition timing retard for the duration of a shift (to lessen drive line shock, or chance of wheel spin, etc.).

- User settable ignition retard when load is above a user specified threshold (for each forward gear above first),

- Four LED indicators for current gear. The default pattern is:The LED pattern is user configurable, which may be useful for those wanting to implement a 7-segment LED/LCD display driver):

The LEDs or LCD display can be set to flash in reverse.

- User configurable output and input patterns for up to 4 shift lever position inputs and up to 7 shift solenoid outputs (to adapt to many automatic transmissions - defaults are for GM 4L60E trans - the 4L80E settings are here). You directly set whether the solenoids are on or off in each gear:

- User configurable PWM on all shift solenoid outputs,

- User configurable PWM on TCC output, with user settable TCC PWM 'ramp-up' based on load to soften TCC apply,

- User configurable 'Dither' (cleaning cycle) in addition to 16x9 PWM table for pressure control solenoid,

- User configurable 'Refresh' on shift solenoid PWM outputs (allows running lower PWM percentages to reduce current draw and heat),

- Adaptive load sensing interprets your driving style and adjusts shifts to reflect 'hard' or easy' driving,

- TunerStudioMS display of shift button status, braking, gear, TCC status, speed, load, odometer, trans temperature, etc.

- Built in code for a 0.5-4.5V line pressure sensor,

- Configurable (pulse/mile) 12V square wave hardware speedometer output for electronic speedometers (you set the pulse per mile),

- As many as four spare outputs that can be set by a user-specified combination of vehicle speed, engine rpm, load, or current gear (with user-set hysteresis to prevent rapidly cycling near the switch points). These can alternatively be used as additional shift solenoids, TCC control, PWM outputs, or 'clutch outputs' (i.e., active only during a shift),

- GM (3 digital inputs) or Ford style (varying voltage) shift lever determination. If the Ford style is used, the 2 inputs not used for shift lever position determination can be used for datalogging voltage signals (temperatures, TPS, MAP, etc.), OR one or both of them can be used as shift solenoids.

- 2/4WD speedometer scaling and switching between independent 2 shift tables using a digital input,

- CAN network to communicate with MS-II™/MicroSquirt®/Sequencer™ to improve control and avoid redundant sensors (with user parameters to allow use with non-B&G code),

- Simultaneous monitoring, datalogging and controller configuration of both MS-II™ and MShift™ with a single laptop running TunerStudio via CAN pass-through (v2.000+ code),

- Comprehensive documents have been written to assist in building, installing and tuning your MegaShift controller, and these are maintained regularly:

Build Guide Components Installation Set-up 4L60E 4L60E Build Guide 4L60E BOM 4L60E Install Guide Configuration and Tuning Guide 4L80E 4L80E Build Guide 4L80E BOM 4L80E Install Guide Configuration and Tuning Guide 41te DRAFT 41te DRAFT 41te BOM DRAFT

41te Install GuideConfiguration and Tuning Guide

The MegaShift™ controller code (for the GPIO hardware) uses the CAN (controller area network) to communicate with MegaSquirt-II™ controllers to get get the current load, battery voltage and engine rpm (and other variables you might want to add to the code). It also allows you to use a laptop connected to the MS-II™ to configure, monitor, and datalog the MShift™ controller. However, the CAN communications can be disabled for stand-alone use of MShift™ on a GPIO board with the load determined from a throttle position sensor (TPS), Manifold Absolute Pressure (MAP) sensor or Manifold Air Flow (MAF) sensor (though the user loses the over/under rev protection and the battery voltage PWM adjustments).

Arduino 4l60e Controller Open Source Download

When CAN is used, this load channel is available to view and log any 0-5 Volt signal (or higher, with an appropriate voltage divider circuit made up of two resistors and a Zener diode) in TunerStudioMS. The line pressure channel is also available for datalogging if not used for the recommended line pressure sensor.

The code starts in one of the two user-selectable auto-modes (sequential shift or skip-shift). Manual mode can be selected at any time by pressing either shift button. Once in manual mode, auto-mode can be re-engaged by:

- pressing and holding both shift buttons simultaneously,

- exceeding either of the user-settable over rev or under rev limits (CAN-enabled only),

- dropping in speed to under 8 mph (from over 20 mph) without selecting first gear in 2WD mode.

- shifting to any of Park, Neutral, or Reverse gears.

In Auto mode:

- Gear is selected according to a 16x9 (speed X load) shift table which selects the target gear based on the current vehicle speed and load (the lookup table is user configurable). Load is based on an average (the period of the averaging is user-settable) of the instantaneous load (load is not sampled while braking).

In Manual mode:

Gm 4l60e Controller

- Full manual control with an upshift button and downshift button (that ground their respective connection to the GPIO board), or optionally if rpm exceeds user-specified redline (for both over-rev and under-rev),

- Revert to auto-mode at any time by pressing both shift buttons simultaneously.

In either mode:

- the TCC (torque converter clutch) is engaged if:

- engine load is below a user-specified threshold, and

- the transmission current gear is at or higher than the user selectable 'minimum TCC gear', and

- the vehicle speed is above user set speed, and

- the trans fluid temperature is above a user specified minimum.

- TCC engagement is forced if the transmission fluid temperature is too high (above a user specified temperature), regardless of load.

Note that the GPIO with the MegaShift™ code only controls the forward gears. You will still require a mechanical shifter to place the transmission into Park, Reverse, or Neutral. The manual shift lever also indicates the maximum gear the controller ought to select - for example, if the shift lever is in second, the transmission controller will limit the transmission to first and second gear only.

The transmission's fluid temperature is sensed by the transmissions internal temperature sensor (the default is 4L60E's GM sensor, but other sensors can be used). A timer channel is used to get the vehicle speed from the VSS sensor on the output shaft, and the TunerStudioMS interface has both a speedometer and an odometer (configurable in miles or kilometers).

For a complete listing of the set-up and tuning parameters for your MegaShift™/GPIO controller, see: Editing MegaShift™ Parameters

GPIO boards from Bowling and Grippo are now available from DIYAutoTune, as well as other MegaSquirt® vendors.

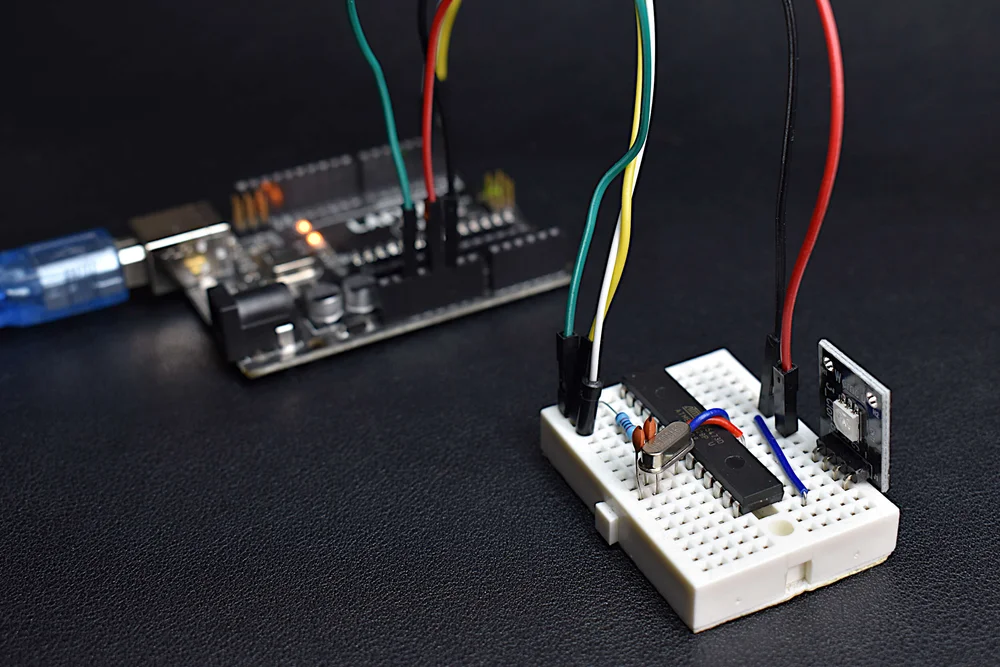

M-DUINO open source PLCs from Industrial Shields control the production line, machinery and stock holding

Arduino 4l60e Controller Open Source Free

About the customer

This company is a family owned business established in 1996 and backed up by the experience of two generations of expertise in manufacturing plastic parts.

It focuses on the design, manufacturing and marketing of plastic protectors, ferrules, caps and stoppers. The company works aligned to quality management standards ISO 9001: 2008. The plant has an area of over 7,000 m2 which is designed to optimize the process of receiving goods, drive the production, manage the stock holding and shipment of goods in the highest quality and speed standards.

The company designs its own molds with calibrated steel and using the latest technology in computerized mechanization. The plastic parts are manufactured mainly in LDPE (Low Density Polyethylene). Parts requiring higher hardness are manufactured in HDPE (High Density Polyethylene). The company does not use PVC according to its environmental friendly philosophy.

They has been evangelists in the open source world. At very early stages, they adapted and integrated open source software in their manufacturing process, and now have implemented open source hardware in their production lines with the Arduino based PLCs from Industrial Shields.

Arduino 4l60e Controller Open Source Software

About 30,000,000 units are produced annually.